Introduction

Ce tutoriel vous aide à changer les disques et plaquettes de frein avant sur Opel mokka 1.6 CDTI 4x2 16V S&S 110 cv

-

-

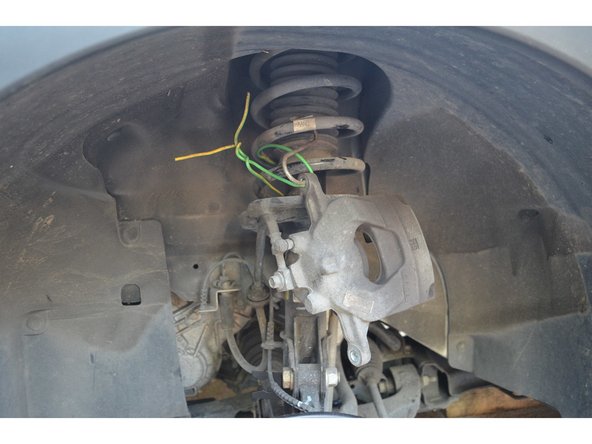

Etrier

-

Support d'étrier

-

L'étrier est fixé par 2 vis de 10mm.

-

Bloquez l'écrou avec une clé de 18mm et desserrez la vis avec une douille de 10mm.

-

-

-

Une fois les 2 vis retirées l'étrier n'est plus retenu.

-

flexible de frein

-

L'étrier ne doit pas reposer sur le flexible de frein et le flexible de frein ne doit pas être pincer.

-

Reliez l'étrier au ressort de suspension à l'aide d'un câble.

-

-

-

En repoussant le piston le niveau du liquide de frein va monter. Veillez à ce qu'il ne déborde pas en retirant le surplus avec une seringue.

-

Avec un serre-joint et une cale en bois repoussez le piston au maximum.

-

-

-

Plaquettes

-

Guides

-

Pour retirer les plaquettes il suffit de tirer dessus pour les faire coulisser dans leurs guides.

-

-

-

Support d'étrier

-

Retirez les vis de fixation avec la douille de 18mm.

-

Préférez une douille 6 pans à une 12 pans pour éviter de riper et d'abîmer la tête de la vis.

-

Les vis sont enduites de frein-filet rouge (résistance élevée). Au besoin faites chauffer à l'aide d'une lampe à souder.

-

-

-

Certains jeux de plaquettes de frein fournissent les agrafes,

-

Insérez un petit tournevis plat entre le support d'étrier et l'agrafe puis faites levier pour les retirer.

-

-

-

Avec un embout Torx T30 retirez la vis de maintien puis retirez le disque.

-

-

-

Les vis de fixation du disque fournies avec les disques neufs ne sont pas bonnes (il faut un M6 et c'est un M8). J'ai donc réutilisé l'ancienne vis.

-

-

-

Avec une brosse métallique nettoyez le support d'étrier et l'étrier en évitant les soufflets en caoutchouc.

-

Le remontage s'effectue en sens inverse.

-

Pulvérisez du nettoyant frein sur les 2 faces du disque pour retirer la paraffine avant de le remonter.

-

Vous pouvez pulvérisez de l'anti-bruit sur les surfaces d'appui des plaquettes afin d'éviter les futurs sifflements.

-

Ne mettez surtout pas d'anti-bruit sur le disque ou les surfaces de frottement des plaquettes.

-

-

-

Une fois le remontage terminé, enfoncez plusieurs fois la pédale de frein pour mettre les plaquettes en appui contre les disques.

-

Vérifiez le niveau de liquide de frein dans le bocal. S'il y en a trop, retirez le surplus à l'aide d'une seringue.

-

Le bocal se trouve derrière le calculateur.

-

Le niveau doit se situer entre le min et le max.

-

Pour le rodage des plaquettes neuves, ne pas effectuer de freinages brusques lors des premiers 200 km.

-

L'efficacité des premiers freinages peut être réduite.

-

Annulation : je n'ai pas terminé ce tutoriel.

6 autres ont terminé cette réparation.

6 commentaires

Bonjour, excellent tutoriel, merci à ceux qui se dévoue pour les réaliser, qui save partager, ce qui n'est pas fréquent dans ce monde de bruts.

andher2020 - Résolu à la publication Réponse

Super tuto, avec cela c’est un jeu d’enfant. Manque juste le frein filet à rajouter au remontage. Tuto très précis jusqu’au diamètre de vis qui effectivement n’est pas le bon avec les disques. Merci pour ce gros travail.

Sébastien Faillon - Résolu à la publication Réponse

Attention tout de même : NE JAMAIS METTRE UN PARPAING CIMENT SOUS LA VOITURE POUR SECURISER - IL PEUT CASSER A CHAQUE INSTANT !!! Privilégier un calage bois .

Sinon super TUTO Merci !!

THIERRY BARAT - Résolu à la publication Réponse

Merci beaucoup pour ce tuto. C’est la première fois que je changeais des plaquettes et disques de frein sur ma voiture. Facile à réaliser quand on suit les étapes et avec l’outillage. Opel Mokka 1.7CDTI Auto.

Pour compléter le tuto : Pour le remplacement des plaquettes et disques pour l’arrière. Suivre les étapes comme pour l’avant. Seul petite précision, avant de procéder au démontage, détacher le câble de frein à main (fixé par 2 vis le long du châssis et qui pend en dessous du moyeu, utiliser 1 douille de 12 mm) afin de lui donner du lest et pouvoir ainsi démonter l’étrier.

Petite précision encore, pour repousser le piston, à l’arrière, il faut impérativement un repousse-piston car celui-ci doit être repoussé et vissé en même temps.

Frédéric PIRET - Résolu à la publication Réponse

merci pour le tuto, je change les plaquettes sur un mokka essence

francis.minaroli - Résolu à la publication Réponse