Introduction

Opération effectuée sur une Mégane 3 1.9 dCi 130ch.

-

-

Mise en sécurité du véhicule : démontage et remontage de la roue

-

Posez des cales derrière les roues encore au sol, passez une vitesse et desserrez le frein à main.

-

-

-

Insérez un tournevis derrière le cache et tapez avec un marteau pour le débloquer et le sortir.

-

Avec une douille de 30mm retirez l'écrou.

-

-

-

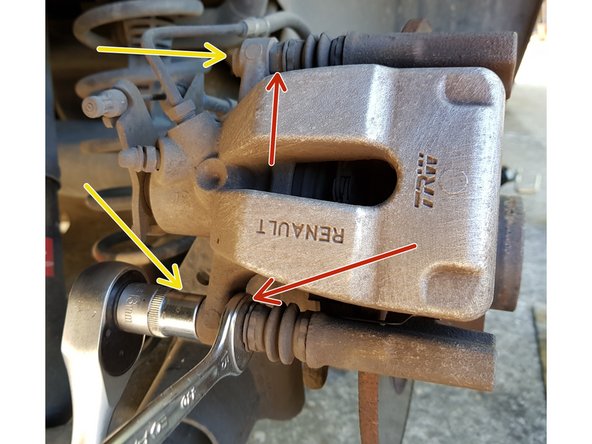

Desserrez à l'aide d'une douille de 13mm.

-

Bloquez avec une clé plate de 15mm.

-

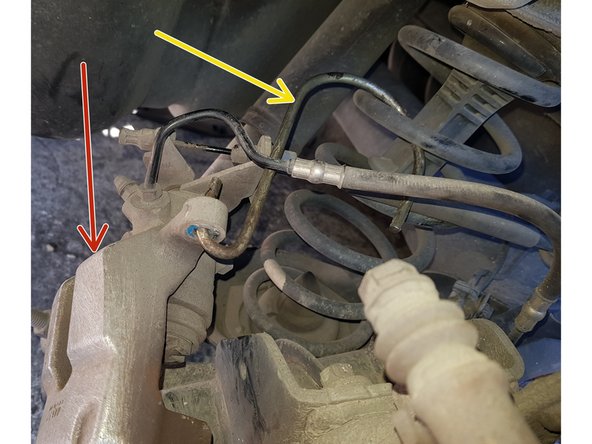

Sortez le flexible de son logement pour avoir plus de jeu.

-

-

-

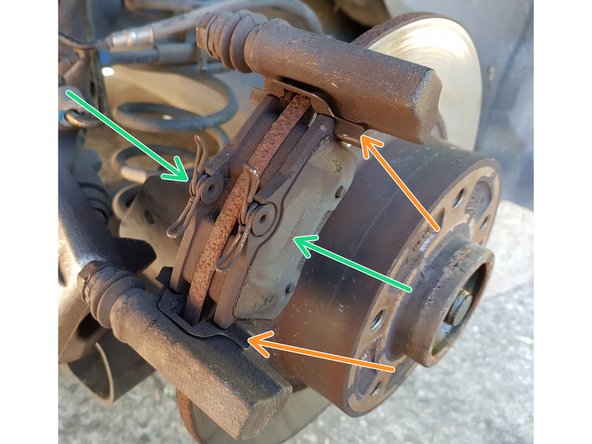

Le support d'étrier est fixé par 2 vis que vous enlèverez avec un embout mâle Torx T60.

-

Le disque de frein sort en tirant dessus.

-

-

-

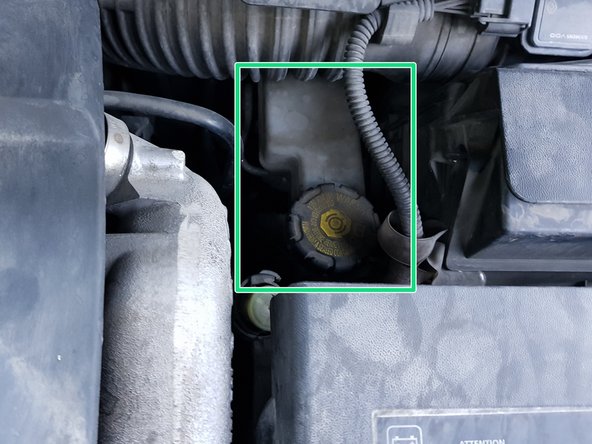

Il se peut que le liquide de frein déborde lorsque vous allez repousser le piston.

-

Vérifiez le niveau du liquide de frein.

-

Repoussez le piston avec un outil adapté car le piston est vissé, un serre-joint est donc inutile ici.

-

-

-

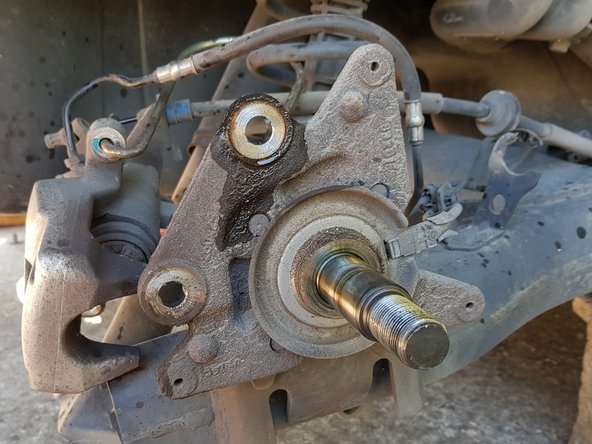

Nettoyez l'axe, le filetage et la portée du roulement.

-

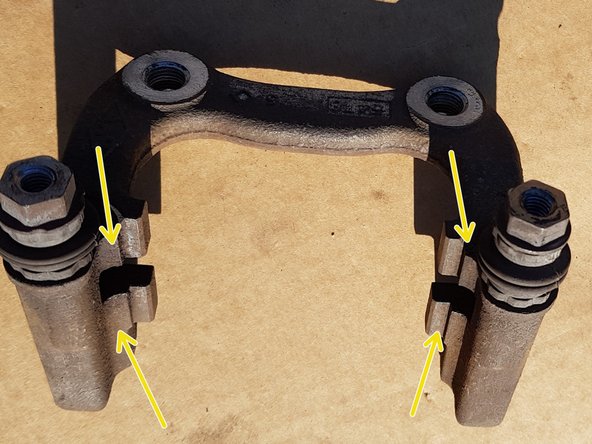

Nettoyez le support d'étrier et notamment la portée des accessoires.

-

-

-

Avant de poser le nouveau disque, passez un coup de nettoyant frein sur les 2 faces afin d'enlever la paraffine qui sert à protéger le métal de la rouille.

-

Le remontage s'effectue en sens inverse.

-

Une fois le remontage terminé, appuyez plusieurs fois sur la pédale de frein afin de remettre en place le piston.

Vérifiez le niveau de liquide de frein dans le bocal.

Pour le rodage des plaquettes neuves, ne pas effectuer de freinages brusques lors des premiers 200 km.

L'efficacité des premiers freinages peut être réduite.

Une fois le remontage terminé, appuyez plusieurs fois sur la pédale de frein afin de remettre en place le piston.

Vérifiez le niveau de liquide de frein dans le bocal.

Pour le rodage des plaquettes neuves, ne pas effectuer de freinages brusques lors des premiers 200 km.

L'efficacité des premiers freinages peut être réduite.

Annulation : je n'ai pas terminé ce tutoriel.

16 autres ont terminé cette réparation.

26 commentaires

Bonjour,

Quels sont les couples de serrage pour l'ecrou du moyeu notament ?

Merci

maracudja07 - Résolu à la publication Réponse

Attention: il n’est pas inutile de rappeler que ce tuto est valable pour un remplacement des disques AVEC roulements. Si les disques neufs ne comprennent pas le roulement, il est nécessaire de récupérer l’ancien roulement et c’est beaucoup plus compliqué…(le catalogue Oscaro comprend des disques avec roulements et des disques sans roulement)

jldeimerly - Résolu à la publication Réponse

ATTENTION : SECURITE : Bonjour , tutoriel très clair et précis. Très bien, mais utiliser des parpaings en guise de chandelles ça comporte un risque énorme, comme sur la photo de l’étape 1 .Ce n’est absolument pas fait et prévu pour supporter le poids d’une voiture. A proscrire !!!!! Un ami d’un collègue de travail a été écrasé par sa voiture en utilisant des parpaings comme chandelles et hélas , il en est mort !!!!!!! Ce genre de photos ne devrait pas apparaître !!!! Il existe des moyens alternatifs aux chandelles pour caler une voiture même plus sécurisants que les chandelles elle mêmes !!!! Mais en aucun cas des parpaings !!!!

hubert.gautier - Résolu à la publication Réponse

Attention sur Mégane 3 j'ai eu besoin d'une douille de 36! Pas 30 comme indiqué. Sinon nickel

lionelboch - Résolu à la publication Réponse