Introduction

Opération effectuée sur une Nissan Note Phase 2 (E11E) 1.4 i 16V 88 cv.

Les roulements neufs qui seront montés sont des SKF - VKBA 3525.

Pour ce véhicule, je n'ai ni manuel d'utilisation ni revue technique par conséquent je ne connais ni les contenances ni les couples de serrage.

Outils

-

-

Dans un premier temps, placez des cales à l'avant et l'arrière de vos roues avant afin d'être sûr que la voiture ne bouge pas, puis desserrez le frein à main.

-

Mise en sécurité du véhicule : démontage et remontage de la roue

-

-

-

Le tambour est bloqué par l'écrou, il faut donc le retirer.

-

Si vous n'avez pas de boulonneuse , vous pouvez utiliser une douille de 30mm et une rallonge qui servira de bras de levier.

-

-

-

Retirez le tambour en le faisant tourner et en tirant dessus en même temps.

-

Profitez-en pour nettoyer vos mâchoires de frein avec du nettoyant frein et la portée du roulement avec une brosse métallique et un chiffon..

-

Référence de l'ancien roulement

-

-

-

Avec une pince à circlips fermante, retirez le circlips afin de pouvoir retirer le roulement.

-

-

-

Anciennes pièces

-

Pièces neuves

-

La portée du roulement doit être propre et sans bavure.

-

-

-

Pulvérisez du lubrifiant pour faciliter le glissement.

-

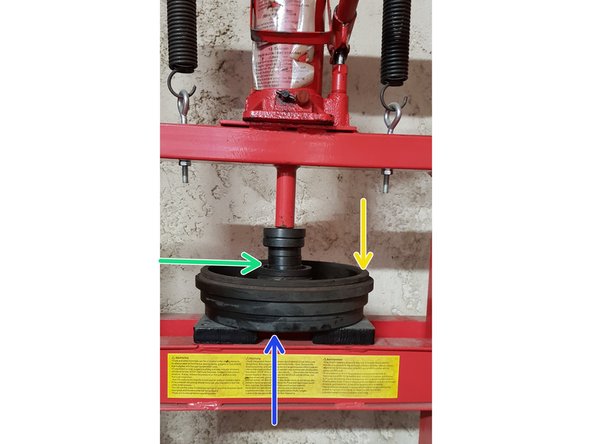

Positionner le roulement dans l'alésage.

-

Le roulement n'a pas de sens.

-

Pour faciliter l'opération vous pouvez au préalable laisser votre roulement dans le congélateur. Le froid va retracter le métal est diminuera les frottements pendant la repose.

-

-

-

Pressez jusqu'a ce que vous arriviez en butée.

-

Disque de 51mm de diamètre.

-

-

-

Roulement en butée.

-

Gorge libre pour le circlips.

-

Une fois le roulement en butée, vous pouvez inserer le circlips neuf.

-

-

-

Pour finir, reposez le tambour, bloquez-le en serrant l'écrou neuf au couple prescrit, puis mettez le cache-écrou et la roue.

-

Vous remarquerez que l'écrou neuf ne laisse pas les 3 filets dépasser comme le faisait l'ancien.

-

Cela vient du fait que le neuf est plus haut.

-

Annulation : je n'ai pas terminé ce tutoriel.

Une autre personne a terminé cette réparation.