Introduction

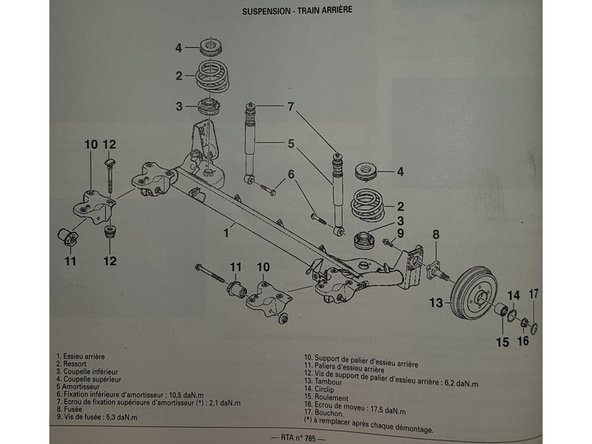

Intervention effectuée sur une Renault Twingo 2 phase 2, moteur 1.5 dCi 75ch.

C'est une voiture que j'ai acheté d'occasion, je n'ai ni manuel d'utilisation ni revue technique par conséquent je ne connais ni les contenances ni les couples de serrage.

Le roulement neuf est un SKF VKBA 3525.

Pour cette intervention, j'ai eu besoin d'outils spécifiques tels qu'une presse et un jeu de disques d'extraction.

-

-

Avec un tournevis plat et un marteau retirez le cache-écrou.

-

-

-

Avec une douille de 30mm retirez l'écrou de moyeu.

-

Lever le véhicule :

-

-

-

-

Desserrez le frein à main

-

Il faut que le véhicule soit correctement calé.

-

Retirez le tambour en le tirant.

-

Pulvérisez du nettoyant frein sur toutes les pièces.

-

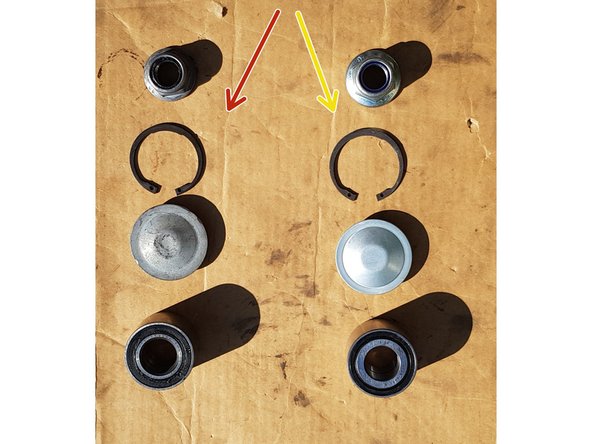

Bague ABS

-

Roulement

-

Circlip

-

-

-

Placez votre tambour dans la presse.

-

Placez un disque de Ø48mm puis pressez.

-

Pensez bien à laisser suffisamment d'espace entre vos cales pour que le roulement puisse sortir librement.

-

-

-

Nettoyez la portée

-

Placez le roulement dans l'alésage.

-

Vous pouvez pulvériser un peu de WD40 pour faciliter le remontage.

-

J'ai utilisé un disque de Ø52mm pour le remontage.

-

Pressez jusqu'à ce que le roulement arrive en butée contre la bague ABS.

-

Ne pas endommager la bague ABS.

-

-

-

Placez le circlip neuf dans la gorge.

-

Anciennes pièces

-

Pièces neuves

-

-

-

Nettoyez l'arbre et mettez-y un peu de graisse.

-

Une fine pellicule de graisse suffit.

-

Replacez le tambour.

-

Serrez l'écrou neuf à 175 N.m.

-

-

-

Ancien écrou

-

Ecrou neuf

-

Les écrous n'ont pas la même hauteur, raison pour laquelle on ne voit pas le même nombre de filets une fois ceux-ci serrés.

-

Annulation : je n'ai pas terminé ce tutoriel.

Une autre personne a terminé cette réparation.