Introduction

Opération effectuée sur VW Polo III Restylée 1.4 i 60cv.

Outils

-

-

Avant toute chose placez le moyeu neuf dans votre congélateur.

-

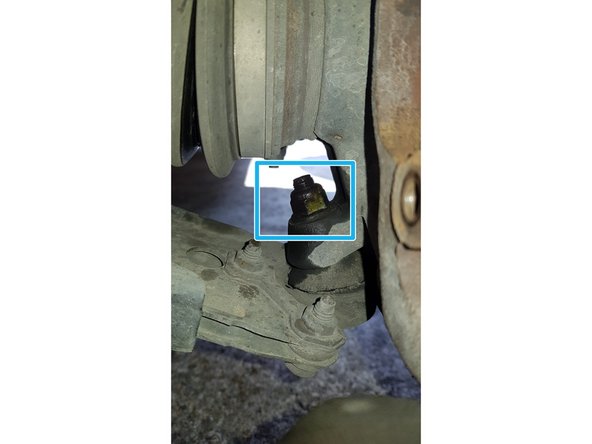

Dévissez l'écrou de cardan avec une douille de 32 pans.

-

Une douille de 12 pans est impérative!

-

Mise en sécurité du véhicule : démontage et remontage de la roue

-

-

-

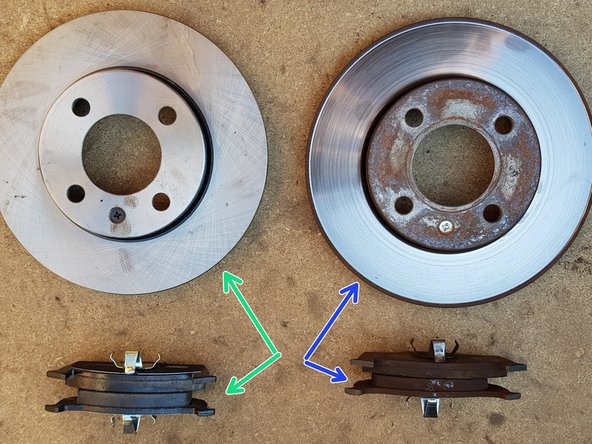

Disque de frein

-

Plaquette côté piston

-

Insérez un tournevis plat entre le disque et la plaquette côté piston et faîtes levier pour repousser le piston.

-

Une fois le piston repoussé vérifiez le niveau du liquide de frein qui doit être entre ...

-

… le mini ….

-

…. et le maxi.

-

Si le niveau dépasse le maxi retirez-en avec une seringue.

-

-

-

Les 2 vis qui maintiennent l'étrier ne font pas la même longueur donc pensez à repérer leur position.

-

Vis du haut

-

Vis du bas

-

-

-

Tirez la partie supérieure de l'étrier vers l'extérieur puis vers le haut.

-

Les faces inférieures des plaquettes sont différentes donc pensez à repérer l'emplacement de chaque plaquette avant démontage puis sortez-les.

-

-

-

Avec un serre-joint et une cale en bois que vous positionnerez sur le piston repoussez celui-ci à fond.

-

Il est possible de repousser le piston entièrement dès l'étape 2 avec le tournevis.

-

Le piston n'est pas vissé donc vous n'aurez pas besoin d'un repousse-piston, un serre-joint fera l'affaire.

-

Posez l'étrier sur l'amortisseur.

-

Veillez à ce que le flexible de frein ne soit pas tendu.

-

-

-

Le disque est maintenu par une vis qu'il est possible de retirer grâce à un tournevis Phillips PH3.

-

Retirez le disque.

-

-

-

Débranchez la connectique

-

Avec une clé BTR 5mm dévissez la vis puis retirez le capteur.

-

-

-

Avec une clé de 18mm débloquez les écrous de la jambe d'amortisseur.

-

Avec une clé de 16mm débloquez l'écrou de la rotule de suspension

-

-

-

Avec une clé BTR de 6mm et une clé plate de 16mm retirez la biellette de direction de la fusée.

-

-

-

Retirez les 2 boulons de l'amortisseur.

-

Avec une clé de 16mm retirez l'écrou de la rotule de suspension.

-

Désaccouplez la fusée de la jambe d'amortisseur.

-

-

-

Sortez le cardan du moyeu puis sortez le moyeu de la rotule de suspension.

-

-

-

Avec une clé de 10mm retirez les 3 vis.

-

-

-

Assurez-vous que l'ensemble soit bien dans l'axe de l'arbre de la presse pour que le moyeu sorte bien droit.

-

Faites en sorte que les cales porte sur l'arbre du moyeu et non pas sur le roulement.

-

-

-

Retirez le circlip pour pouvoir procéder à l'extraction du roulement.

-

-

-

Avec du papier absorbant nettoyez la portée du roulement.

-

-

-

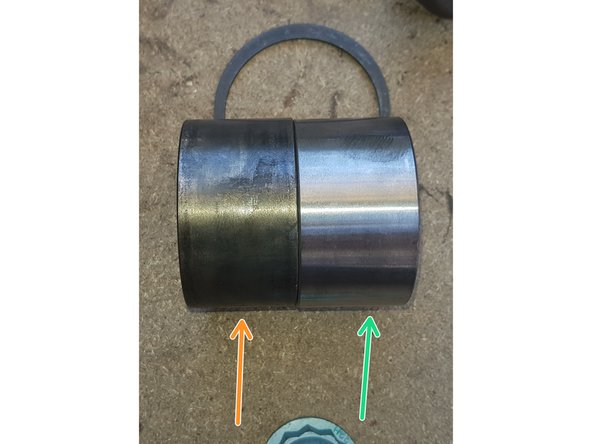

Anciennes pièces

-

Pièces neuves

-

Avec le roulement neuf sont livrés la graisse, l'écrou de cardan et 2 circlips.

-

Vous n'aurez besoin que d'un circlip.

-

-

-

Positionnez la fusée dans le sens inverse que celui dans lequel elle était lors de l'extraction du roulement.

-

Enduisez la portée du roulement de graisse.

-

Présentez le roulement neuf.

-

Placez une cale au-dessus.

-

Veillez à ce que le roulement soit bien positionné pour qu'il puisse rentrer bien droit dans la fusée puis avec la presse enfoncez-le dans son logement.

-

-

-

Placez le circlip dans son emplacement pour bloquer le roulement dans la fusée.

-

Côté extérieur

-

Côté intérieur

-

-

-

Sortez votre moyeu du congélateur puis présentez-le sur la fusée.

-

Placez une cale au-dessus.

-

Veillez à ce que le moyeu soit bien positionné pour qu'il puisse rentrer bien droit dans le roulement puis avec la presse enfoncez-le dans son logement.

-

-

-

Replacez la plaque de protection du disque sur la fusée puis l'ensemble sur le véhicule en remontant les 2 boulons de la jambe d'amortisseur, l'écrou de la rotule de suspension, l'écrou de cardan et la biellette de direction.

-

Enduisez la portée du moyeu de graisse cuivrée.

-

-

-

Avec une brosse métallique nettoyez les guides de plaquettes

-

Puis pulvérisez de l'anti-bruits afin d'éviter les sifflements au freinage.

-

-

-

Pulvérisez du nettoyant-frein sur l'étrier pour retirer le plus gros de la poussière.

-

Puis nettoyez-le avec une brosse métallique.

-

-

-

Pulvérisez de l'anti-bruits sur toutes les surface de contact.

-

Ne pas en pulvériser sur les surfaces de frottement.

-

-

-

Pulvérisez du nettoyant-frein sur les 2 faces du disque.

-

Repositionnez le disque et fixez-le avec la petite vis fournie avec le disque neuf.

-

Repositionnez les plaquettes dans l'étrier en les mettant aux bonnes places puis fixez l'étrier avec les 2 vis.

-

-

-

Voici l'anti-bruits que j'utilise et qui est particulièrement efficace.

-

Une fois le remontage terminé, enfoncez plusieurs fois la pédale de frein pour mettre les plaquettes en appui contre les disques.

-

Vérifiez le niveau de liquide de frein dans le bocal.

-

Pour le rodage des plaquettes neuves, ne pas effectuer de freinages brusques lors des premiers 200 kms.

-

L'efficacité des premiers freinages peut être réduite.

-

Annulation : je n'ai pas terminé ce tutoriel.

3 autres ont terminé cette réparation.

3 commentaires

Bonjour, il me semble que une fois tout remonter une géométrie est nécessaire non?

meiersteph - Résolu à la publication Réponse

très clair, bien étayé par les images.

Merci à l’auteur.

Jean-Luc (un bricoleur)

jean-luc.mottet - Résolu à la publication Réponse