Introduction

Peugeot 307 2.0HDI 90 CV

Vidéo d'introduction

-

-

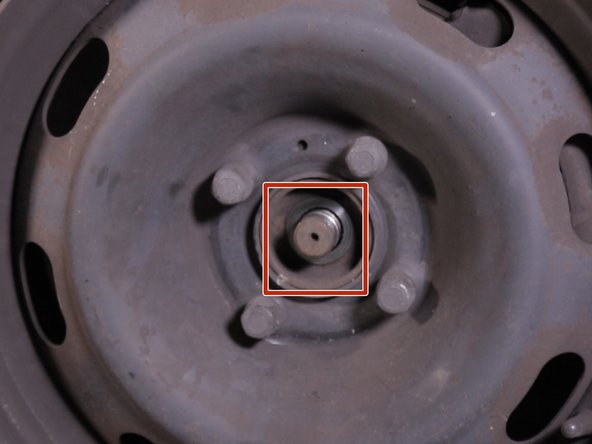

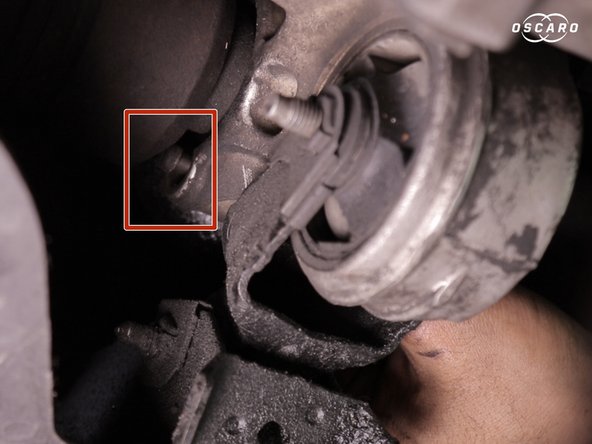

Avant de soulever la voiture à l'aide d'un tournevis plat retirer la goupille

-

-

-

Retirer la cage de l’écrou de cardan

-

-

-

Placer la croix avec une douille de 36 sur l’écrou de cardan

-

Desserrer l’écrou de cardan à l'aide d'une barre placée par exemple dans un bras de la croix

-

-

-

Dévisser l’écrou de cardan à la main et retirer le

-

-

-

Dévisser les 4 boulons de la roue et retirer la.Placer le véhicule sur chandelle à l'aide d'un cric : Mise en sécurité du véhicule : démontage et remontage de la roue

-

-

-

Desserrer le bouchon de la boite de vitesse

-

Placer un bac sous le bouchon

-

Retirer le bouchon et vidanger

-

-

-

Retirer le joint du bouchon et nettoyer le bouchon

-

-

-

Replacer le nouveau joint sur bouchon

-

Replacer le bouchon et serrer une fois que toute l'huile s'est vidée

-

-

-

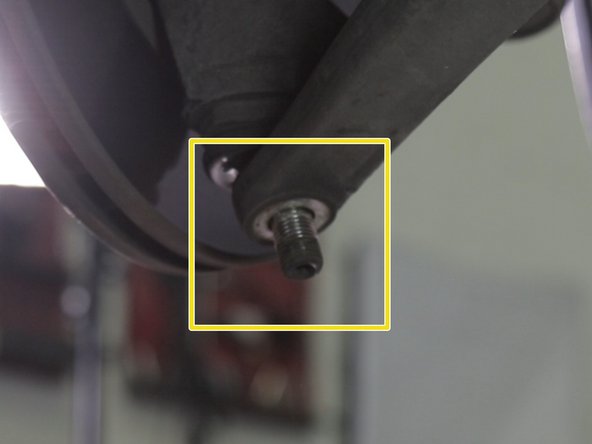

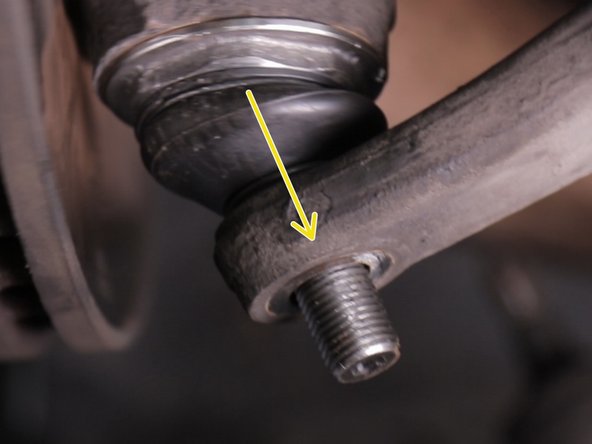

Desserrer l’écrou de la rotule de pivot et retirer le

-

-

-

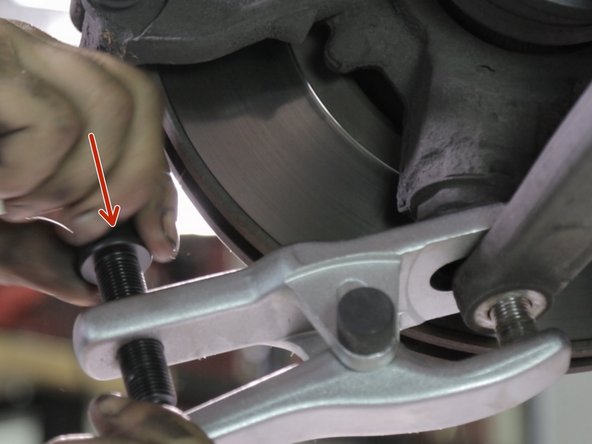

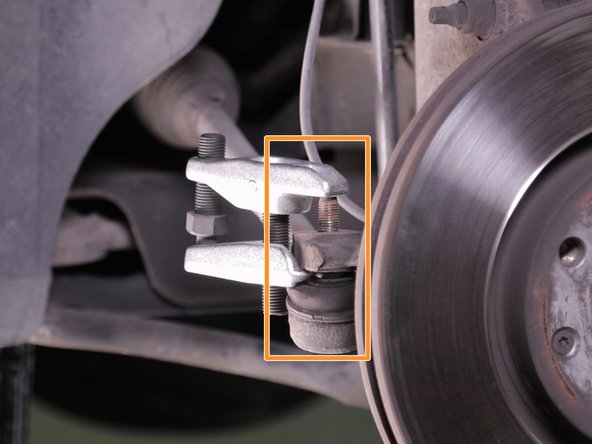

Placer un extracteur de rotule entre le triangle et la rotule.

-

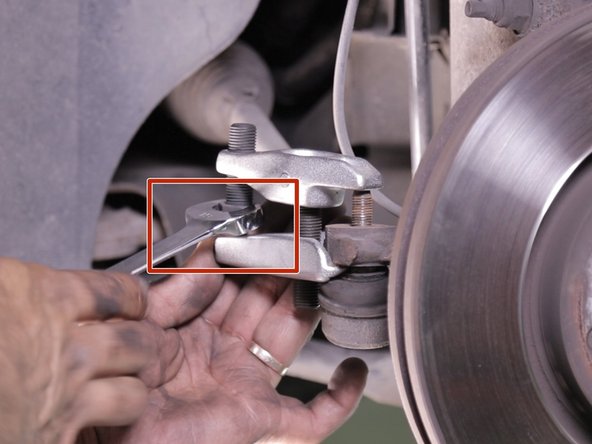

Serrer la vis de l'extracteur pour décoller la rotule

-

-

-

Retirer l'extracteur

-

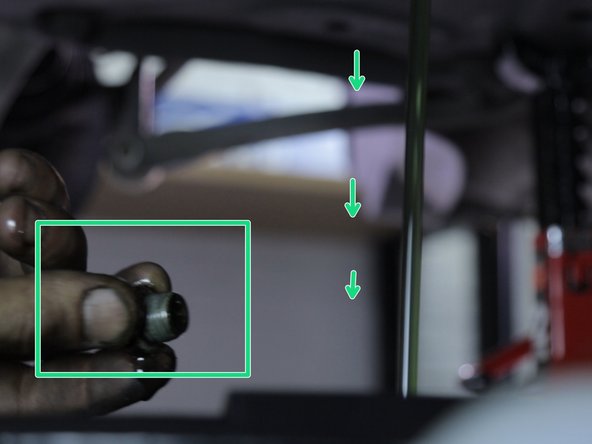

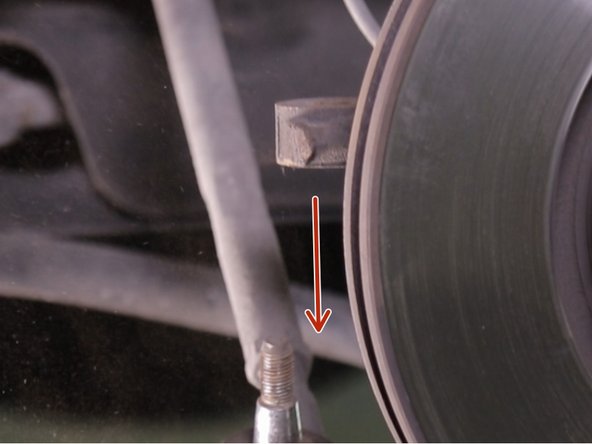

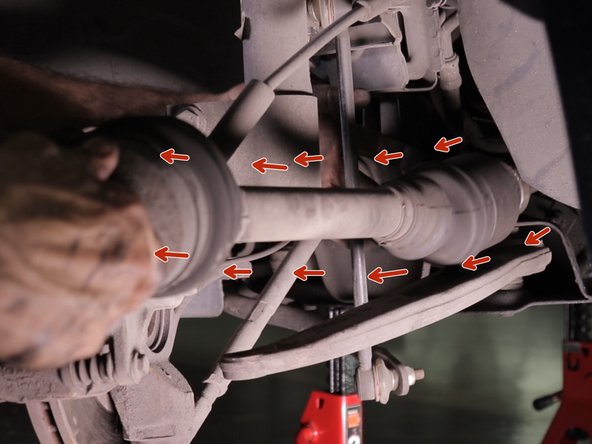

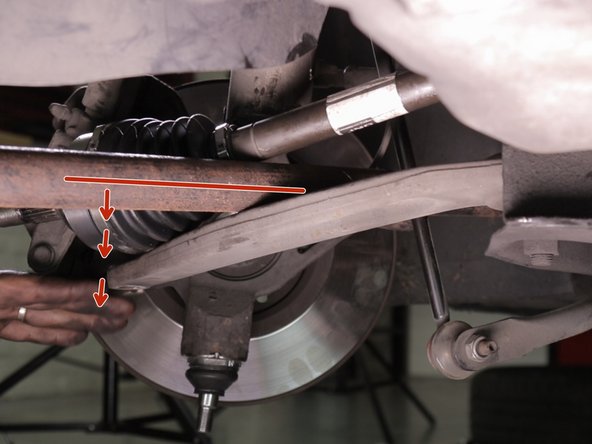

Glisser une barre jusqu'au bas de caisse entre le cardan et le triangle.

-

Dégager le triangle de la rotule en faisant levier vers le bas puis retirer le barre délicatement

-

-

-

A l'aide d'une clé de 16 dévisser l’écrou de la rotule de direction

-

Retirer l'ecrou

-

-

-

Placer l'extracteur de rotule entre la rotule et le porte moyeu

-

Serrer le vis de l'extracteur pour décoller la rotule

-

-

-

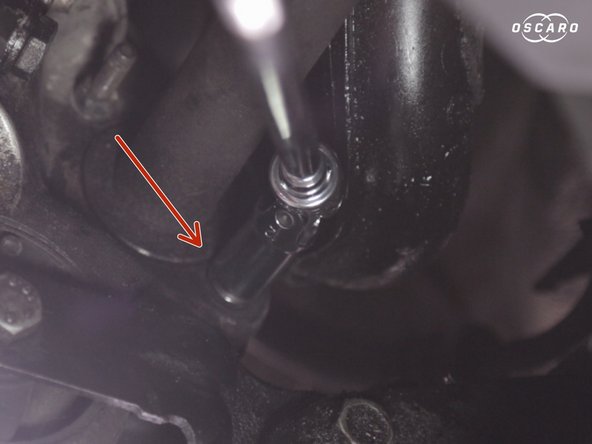

Avec une clé de 11 Desserrer sans les retirer les deux écrous de bride du roulement du cardan qui traverse le support moteur inférieur

-

-

-

Utiliser une douille longue de 11 pour faciliter l'intervention

-

-

-

Libérer les brides en les faisant reculer puis pivoter à 180 degrés

-

-

-

Ecarter le moyeu du cardan pour le degager

-

Si le cardan est collé repositionner l’écrou et tapoter avec le marteau

-

-

-

Faire pivoter le moyeu et extraire le bout du cardan.

-

Retirer le cardan en tirant vers vous délicatement

-

-

-

Placer une clé plate de 19 dans le joint spi de cardan sur le boite de vitesse

-

Faire levier avec la clé pour l'extraire

-

-

-

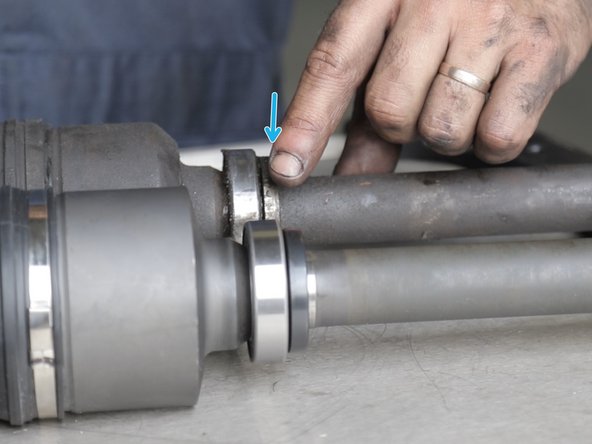

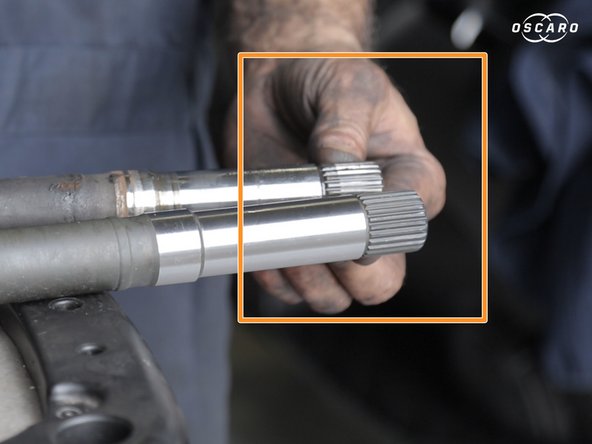

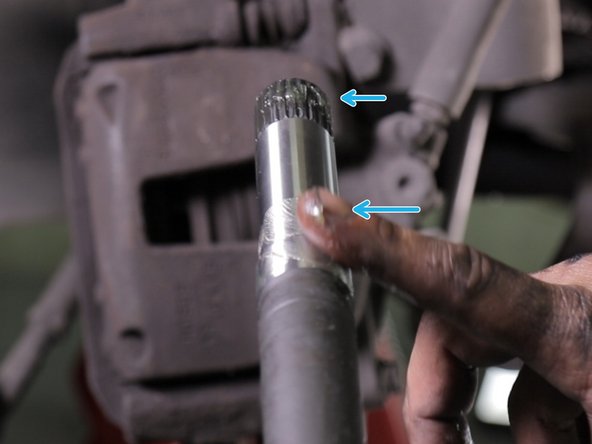

Comparer l'ancien et le nouveau cardan (dimensions)

-

longueur traversant le moyeu

-

L'emplacement du roulement

-

les cannelure sur le cardan coté de la boite de vitesse

-

-

-

Avant la repose dans certains cas l’écrou est proposé avec le cardan retirer le

-

Comparer l'ancien et le nouveau joint (diamètres et épaisseur)

-

-

-

Lubrifier le joint avec de l'huile

-

Repositionner le joint et tapoter avec le marteau pour l’emboîter, attention ne pas l'enfoncer plus le rebord de la boite de vitesses

-

-

-

Nettoyer puis graisser la portée du roulement

-

Graisser les bons du cardan

-

Assurez vous de la bonne position des brides avant d'enfiler le cardan

-

-

-

Enfiler le cardan délicatement en guidant l'entrée de boite puis jusqu'en butée du roulement

-

-

-

Repositionner la barre pour écarter le triangle afin d'emboîter le bout du cardan dans le moyeu

-

Par précaution réaliser cette opération à deux

-

-

-

Maintenir la barre en position pour insérer la rotule dans le triangle

-

-

-

Resserrer la rotule du triangle avec une douille de 22

-

-

-

Repositionner et serrer les deux brides du roulement de cardan

-

-

-

Repositionner et serrer la rotule de direction avec la douille de 16

-

Si le serrage est impossible car la rotule tourne dans le vide , placer un cric sous la rotule pour la bloquer

-

-

-

Rapprocher l’écrou du cardan au maximum

-

Descendre le véhicule au sol et serrer les 4 boulons de la roue

-

Bloquer l’écrou de cardan avec une barre si necessaire

-

-

-

Replacer la cage de l’écrou en respectant les trous de la goupille

-

Replacer la goupille à l'aide d'un tournevis

-

-

-

Retirer avec une clé de 17 le bouchon de mis à l'air libre au dessus de la boite de vitesse

-

-

-

Placer le tuyau de la seringue dans le trou pour le remplissage

-

Verser 1,9 litre d'huile de boite avec la seringue (75w80)

-

Refermer le bouchon de la boite de vitesse

-