Introduction

tutoriel réalisé sur une Renault Captur 1.5 Dci 90

-

-

Lever le véhicule,et le mettre sur chandelles: Mise en sécurité du véhicule : démontage et remontage de la roue

-

Démonter les roues à l'aide de la croix

-

Braquer le disque pour accéder plus facilement au vis

-

-

-

Ouvrir le bocal de liquide de frein

-

Repousser le piston à l'aide d'un tournevis plat.

-

-

-

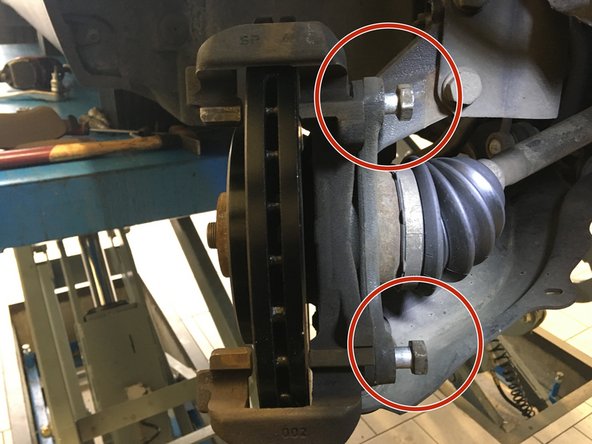

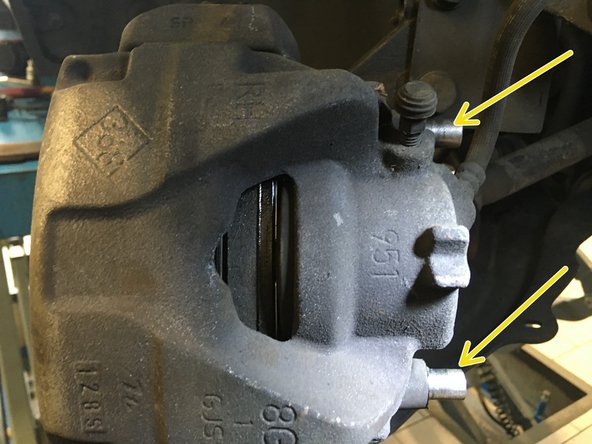

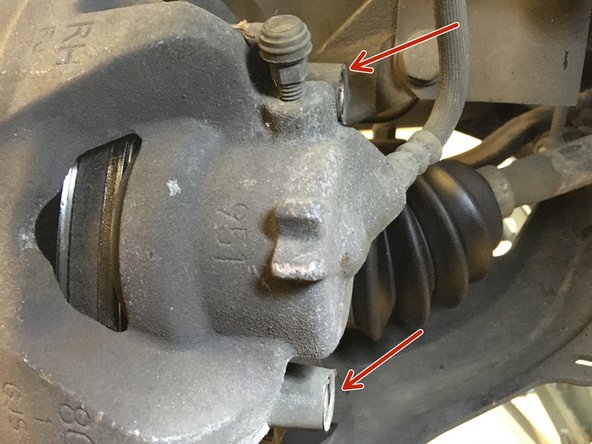

Démonter l'étrier

-

Faite attention aux flexible de frein. Celui ci ne doit jamais être en contrainte

-

-

-

Démonter les deux vis de 18 à l'aide du cliquet et de la douille

-

Retirer la chape

-

-

-

A l'aide du cliquet et de l'embout Torx T30 dévissé les deux vis de T30 qui maintient le disque en place

-

Retirer l'ancien disque, si besoin aidée vous d'un marteau

-

Nettoyer la porté du moyeu à l'aide de papier a poncer ou d'une brosse métallique

-

-

-

Monter le nouveau disque

-

A l'aide du cliquet et de l'embout de T30 visser les deux vis qui maintienne le disque en place

-

-

-

Remonter la roue

-

Serrer les vis au couple à l'aide de la clé dynamométrique

-

-

-

Faite de même pour l'autre coté

-

Remonter les roues en respectant les couples de serrage

-

Reposer le véhicule au sol

-

Pomper plusieurs fois sur la pédale de frein

-

Vérifier le niveau de liquide de frein qui doit ce trouver entre le mini et le maxi

-

Les premier freinage doivent être effectué a faible allure pour déglacer les frein

-

Il est nécessaire d'effectuer un rodage de 500 km après le remplacement des frein avant.

Il est nécessaire d'effectuer un rodage de 500 km après le remplacement des frein avant.

Annulation : je n'ai pas terminé ce tutoriel.

7 autres ont terminé cette réparation.

7 commentaires

Bonjour.

penser lors du remontage de la chape à mettre un peu de frein filet sur les vis

C est un embout T40 pour les vis de maintien du disque

Bonjour, vous écrivez : serrer au couple avec une clé dynamométrique. très bien mais quel couple? (même + ou -)

110N.m pour les goujons de roue

105N.m pour la chape

28N.m pour l'étrier sur la chape (colonnettes)

14N.m pour le disque (les 2 vis Torx T40)

Bonjour,

Vous ne parlez pas des capteurs d'usure? Pour quelle raison?

Cdlt

Jpvivien