Introduction

Remplacement du turbocompresseur moteur sur C4 HDI 90

Si votre turbo a un ou plusieurs symptômes suivant il faut le remplacer :

- perte de puissance

- sifflement important

- jeu excessif

- fumée et perte d huile

-

-

Le moteur HDI 1.6 est très sensible a la qualité de l'huile et la casse turbo peut être dû a un manque d'huile ou une huile avec trop de particules

-

-

Faire une première vidange avec une huile, bas de gamme type 15W40 pour "nettoyer le moteur"

-

Laisser tourner le moteur au ralenti pendant 15 minutes pour que le filtre neuf retire un le maximum de particules

-

Faire une seconde vidange avec l'huile normale

-

Cette fois ci la jauge doit sortir avec un huile très claire et non une huile noire

-

-

-

Dévisser la vis de droite

-

Dévisser le collier de fixation

-

Dévisser le collier de fixation de la durite et du conduit

-

Débrancher la durite radiateur du conduit

-

-

-

Pivoter le conduit et déclipser du plot plastique situé derrière

-

Sortir le conduit

-

Ranger les 2 vis et le conduit pour ne rien perdre

-

-

-

Désserrer les 2 colliers metaliques

-

Sortir le conduit

-

Ranger le conduit pour ne rien perdre

-

-

-

Dévisser les 7 vis de fixation

-

Attention a ne pas abîmer le radiateur moteur pendant le retrait

-

Faire descendre et pivoter vers l'arrière la protection thermique pour la sortir du compartiment moteur

-

Ranger la protection et les 7 vis

-

-

-

Retirer le plot plastique

-

Dévisser les 2 fixations

-

Ranger la protection et les 2 vis + le plot

-

-

-

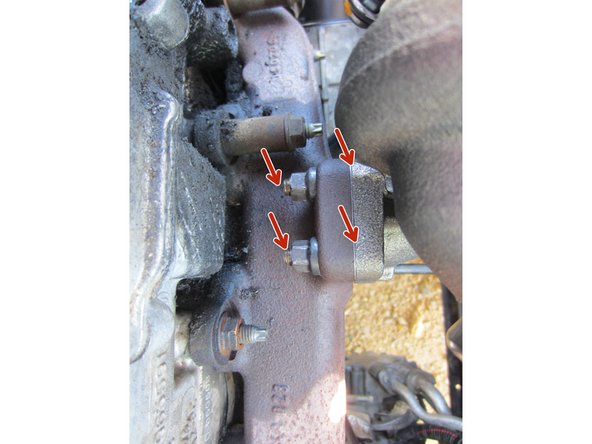

Pulvérisez du dégrippant sur les fixations rouillées , cela vous facilitera le démontage

-

sur le collier d'échappement en sortie de turbo

-

Sur les 4 écrous de la pipe d'échappement

-

sur le collier d'échappement en sortie de catalyseur

-

-

-

Dévisser la vis de serrage du colliers

-

Ecarter le collier avec une vis et 2 écrous (en serrant les 2 écrous cela écarte le collier)

-

Décaler le vers la gauche pour libérer le catalyseur

-

Faire de même sous le moteur entre le catalyseur et la ligne d'échappement

-

-

-

Dévisser les 2 écrous de fixation du catlyseur

-

Retirer le catalyseur par le bas

-

Ranger le catalyseur, les colliers et les écrous de fixation + le support

-

Retirer et ranger la protection thermique

-

-

-

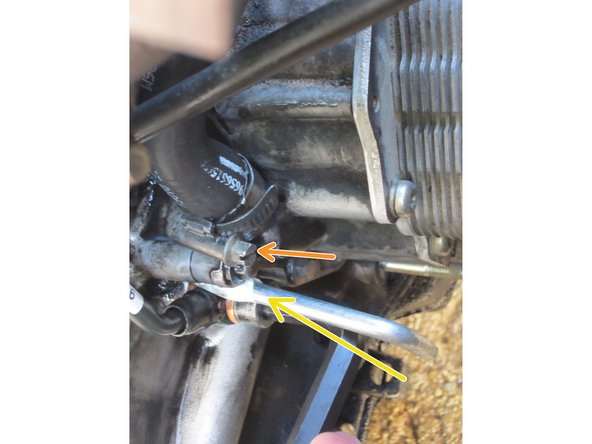

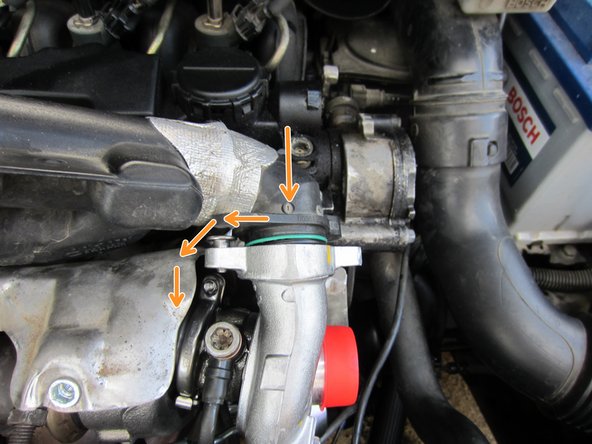

Démonter la vis 6 pans d'arrivée d huile en sortie moteur

-

Desserrer le collier de serrage de la durite de retour d'huile

-

Démonter la vis 6 pans d'arrivée d huile sur le turbo

-

Retirer et ranger la durite et la vis plus le collier

-

-

-

Débrancher le tuyau de dépression

-

Desserrer les 4 écrous de fixation du turbo sur la pipe d'échappement

-

Retirer le turbo du moteur

-

-

-

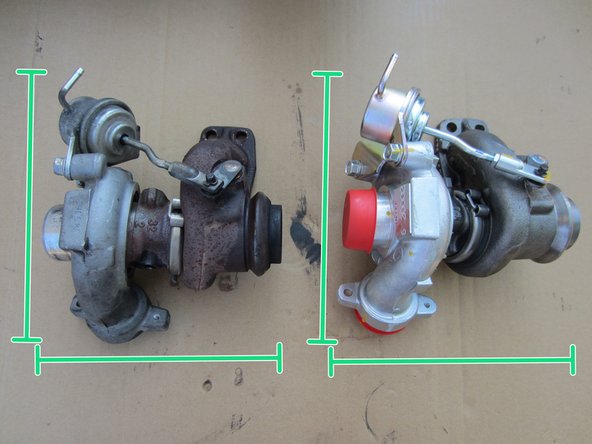

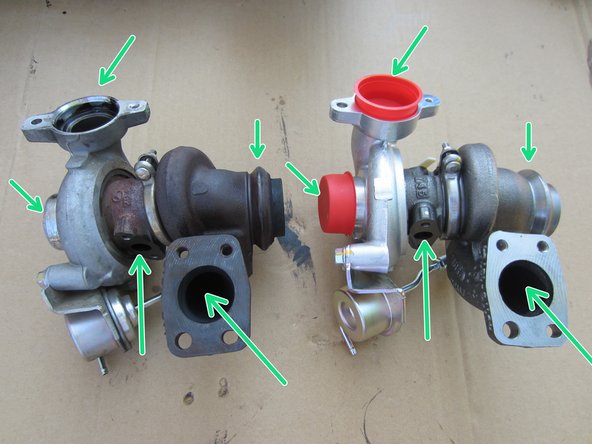

Vérifier les pièces à démonter sur l'ancien turbo pour installer sur le nouveau

-

durite huile

-

les goujons

-

la vis torx

-

comparaison des 2 turbos (taille, connections , etc...)

-

-

-

Précharge d'huile avec une seringue

-

Remontage durite, vis torx et goujons

-

-

-

Fixer le turbo avec les 4 écrous

-

Reconnecter le tuyau de dépression

-

-

-

Retirer le filtre de rodage sur la vis creuse du bas

-

Connecter et serrer le collier de la durite de retour d'huile

-

Serrer la vis creuse de retour d'huile avec une clé pour caler le raccord (environ 7mm de diamètre)

-

Serrer la vis creuse de retour d'huile avec une douille pour caler le raccord (environ 20mm de diamètre)

-

-

-

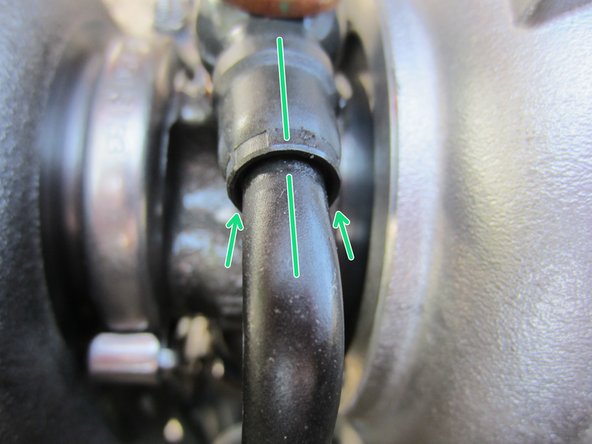

Le tube doit être parfaitement centré sur le raccord du bas et du haut

-

Risque de fuite d'huile, et donc casse turbo

-

si besoin refaire l'étape précédente

-

-

-

Remonter la protection arriere

-

Remonter la fixation

-

Remonter le catalyseur

-

fixer le catalyseur avec les 2 ecrous

-

fixer le catalyseur sur le turbo et sur la ligne d'échappement avec les 2 colliers metalliques

-

-

-

Remonter la protection haute + le pion plastique

-

Remonter la durite de sortie d air en la faisant pivoter

-

Serrer la vis et les 2 colliers

-

-

-

Remonter la durite et serrer les 2 colliers

-

Remonter la protection thermique et serrer les 7 vis

-

-

-

Déconnecter les 4 injecteurs (pour éviter le démarrage du moteur et commencer la lubrification du turbo)

-

Faire tourner le démarreur pendant 30 secondes pour que la circulation d'huile commence avant la rotation du turbo

-

Si on démarre le turbo sans cette étape, cela peut conduire a une usure irrémédiable du turbo

-

Reconnecter les injecteurs et démarrer la voiture, laisser tourner au ralenti pendant 10 min

-

Suite a la déconnexion des injecteurs il va y avoir des alarmes de pollution, après plusieurs démarrage elles disparaîtront

-

Annulation : je n'ai pas terminé ce tutoriel.

5 autres ont terminé cette réparation.

21 commentaires

Bonjour vous parler pas de la crépine normalement faut ma remplacer

thomas.du19 - Résolu à la publication Réponse

j ai fais tout comme vous très bon tuto j’ai contrôlé mon n huile arrive bien suite a sa après 2000km sa a cassé une 2eme fois je comprend pas tout a était changé en plus .moi ses Eric merci a toi

lib_ana_eri - Résolu à la publication Réponse