Introduction

Ce tutoriel est réalisé sur Volkswagen Passat B6 - 1.9 TDI 105

-

-

Deviser les 11 vis de T25 et T40

-

Retirer la plaque sous moteur

-

-

-

A l'aide d'une clé plate de 18 détendre le galet tendeur

-

Insérer une pige pour bloquer le galet tendeur afin de retirer la courroie

-

-

-

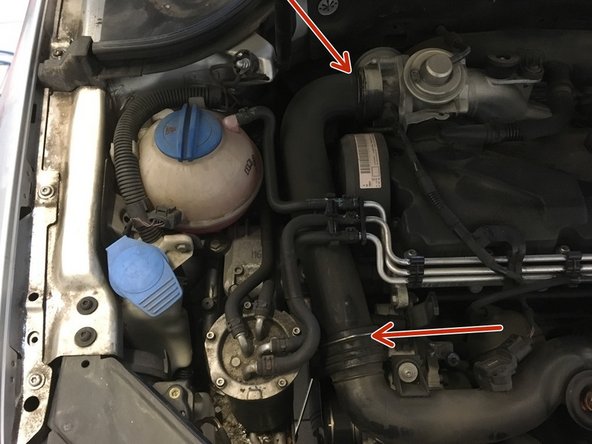

Deviser les deux vis de T25 et basculer le bocal pour accéder au support moteur

-

-

-

Installer un cric sous le moteur et soulever le légèrement pour pouvoir retirer le support moteur

-

-

-

Deviser les deux vis de 16

-

Deviser les deux vis de 18

-

Retirer le support moteur

-

-

-

Retirer le cache distribution en déclipsant les trois clips

-

Retirer le support moteur

-

-

-

Dévisser les 5 vis de 10

-

Retirer le cache distribution

-

-

-

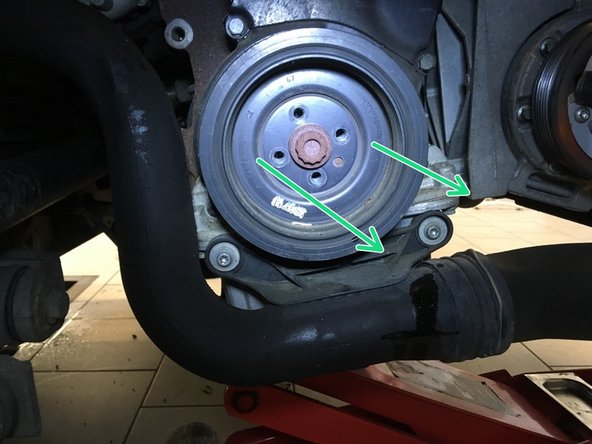

Tourner le moteur à l'aide de la douille de E24 jusqu'à aligner les marquage

-

Insérer les piges de calage pour bloquer l'arbre à came et le vilebrequin

-

-

-

Desserrer la vis de 15 et détendre le galet tendeur

-

Repérer le schéma de passage de la courroie puis retirer la

-

-

-

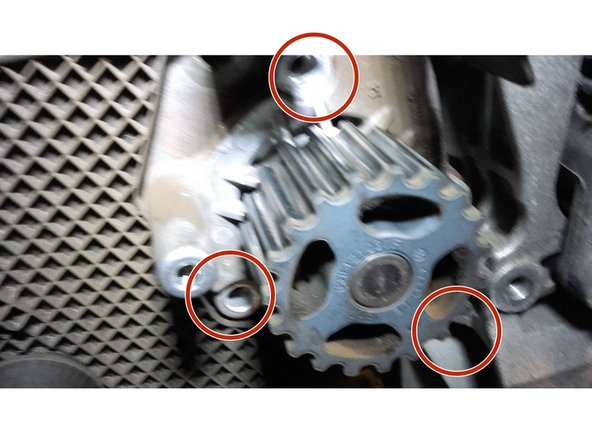

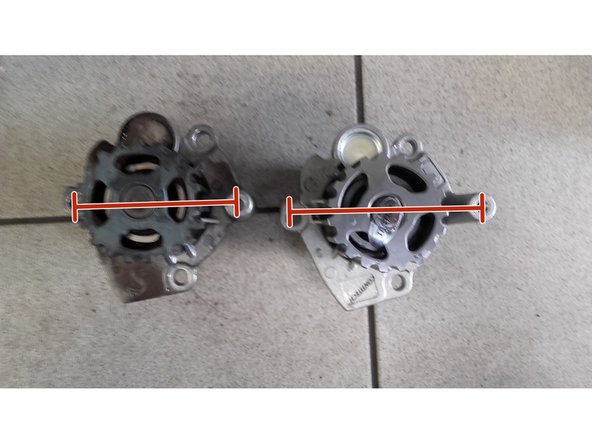

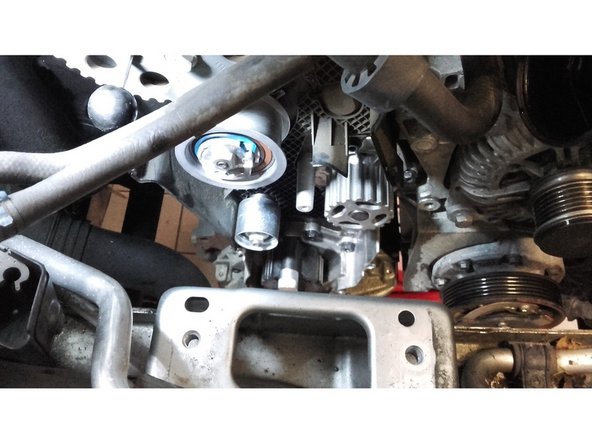

Deviser les 3 vis de 10

-

Retirer la pompe à eau

-

Si vous n'aviez pas au préalable vidangé votre circuit de refroidissement, celui ci s'écoulera à la dépose de la pompe a eau. Placer donc un bac de récupération sous celle ci

-

-

-

Installer le nouveau galet et serrer la vis de 15 au couple constructeur

-

-

-

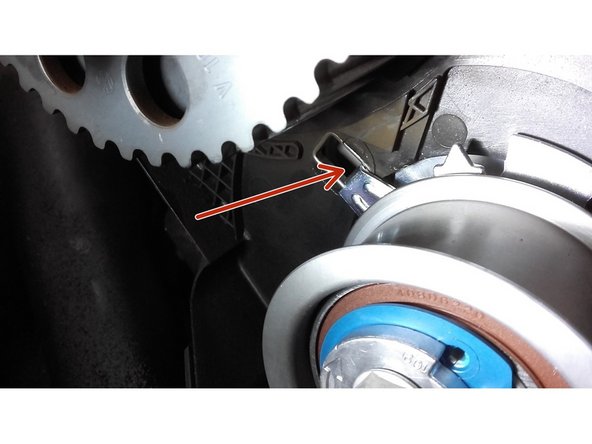

Installer le nouveau galet tendeur en prenant soin de positionner la patte dans son logement

-

-

-

A l'aide de la clé BTR de 6 mettre la courroie en tension

-

Aligner le repère pour effectuer la bonne tension

-

Serrer l'écrou de 15 au couple constructeur

-

-

-

Faite deux tours de moteur à l'aide du cliquet et de la douille de E24

-

Vérifier qu'une fois les deux tour effectué les piges entre de nouveau dans leur logement

-

Retirer les piges

-

Remonter le tout dans le sens inverse du démontage

-

-

-

Verser le liquide de refroidissement dans le bocal

-

Démarrer le moteur

-

le circuit de refroidissement se purge seul sur ce model de véhicule

-

Laisser tourner le moteur jusqu'à ce que le ventilateur de refroidissement se mette en marche plusieurs fois

-

Arrêter le moteur, et vérifier le niveau après refroidissement complet du moteur

-

Annulation : je n'ai pas terminé ce tutoriel.

4 autres ont terminé cette réparation.

13 commentaires

Bonjour,

dans l’étape 16 vous demandez de mettre les repères correctement, hors sur la photo on voie que le repère est en PMH et n’est pas aligne avec le system de calage…

c’est une erreur ou pas ?

Merci

Bonjour très bon tuto. Parcontre est-il normal que la flèche indiquant le sens de rotation indique un sens anti horaire hors la tension sur ce model est faite dans le sens horaire repérée par une flèche sur le galet tendeur.. merci d'avance

bonjour

merci de vos aides !

MAIS JE PENSE PAS QUE CE SOIT SUR UNE AUDI A4 TYPE B6

non ??

Comment faire deux tours de moteur alors que les piges sont en place .

Ou alors l’ordre est mauvais dans les opérations.