Introduction

Les symptômes d'une biellette défectueuse sont assez simples :

- Vous n'arrivez plus à passer une vitesse ou enclencher la marche arrière.

- Le levier de vitesse montre un jeu important, même avec une vitesse enclenchée.

Cela arrive souvent après des passages de rapports trop brutaux en conduite sportive.

-

-

Commencer par lever l'avant du véhicule avec un cric jusqu'à ce que les roues avant ne touche plus le sol

-

Placer des chandelles sous le véhicule pour le sécuriser

-

-

-

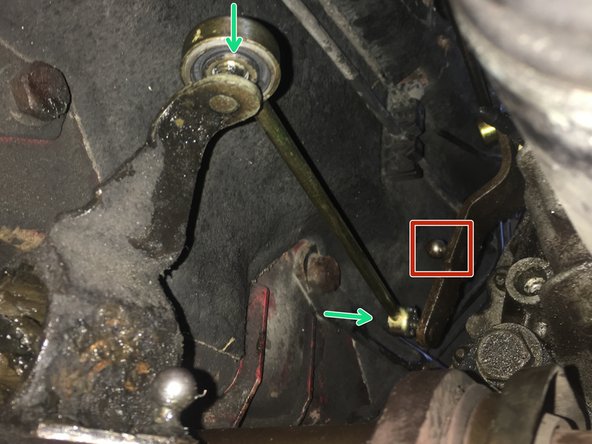

Les trois biellettes se situent entre la boite de vitesse et l'habitacle de la voiture, sous le moteur. Vous les trouverez facilement en suivant le chemin du collecteur d'échappement

-

Vous disposez d'un total de trois biellettes, ici, côté levier de vitesse

-

Ici, côté boite de vitesse

-

-

-

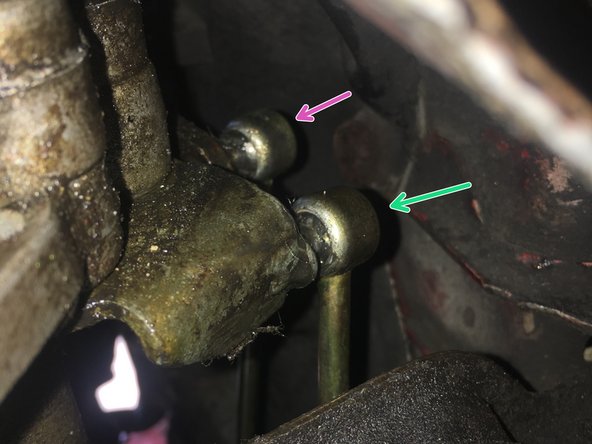

Pour les grosses têtes de biellette utilisez une clé plate de 17 afin de faire levier. Placez la clé plat entre la tête et son support

-

Faites levier pour décrocher la tête de la biellette

-

-

-

Placer la clé plate de 13 pour la petite tête de la seconde biellette

-

Faire levier et décrocher la biellette

-

-

-

Placer la clé plate de 17 entre la tête de la biellette et son support

-

Faire levier pour déposer la biellette

-

-

-

La troisième et dernière biellette est la plus longue et son emplacement plus haut (les deux premières sont en fait le même modèle de biellette)

-

Placer la clé plate de 13 entre la tête et son support

-

Faire levier pour déposer la première tête de la biellette

-

-

-

Placer la clé plate de 17 pour la grosse tête de la dernière biellette

-

Faites levier pour déposer la dernière biellette

-

-

-

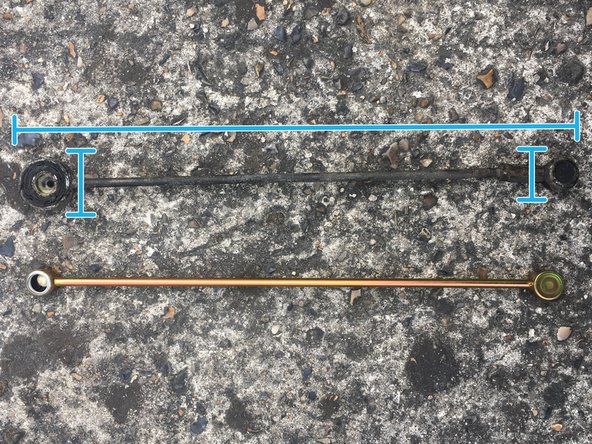

Une fois les trois biellettes déposés vous devez maintenant comparer les nouvelles biellettes afin de vous assurer de replacer les bonnes pièces

-

Parmi les trois biellettes déposées, une avait déjà été "réparée"

-

Pour la nouvelle biellette longue n'est pas semblable car elle ne possède par de grosse tête mais le diamètre du trou et sa longueur son semblables à l'ancienne

-

Toutes les biellettes sont semblables, je peux maintenant reposer les nouvelles !

-

-

-

Je commence par reposer la troisième biellette car il s'agit de la plus difficile d'accès et j'y aurait difficilement accès une fois les deux autres reposés

-

Il est conseillé de nettoyer/dégripper l'emplacement des biellettes avec un dégrippant. Vous devez ensuite y appliquer une noisette de graisse pour contribuer à sa longévité.

-

Pour reposer la biellette, rien de plus simple : emboîter la tête de biellette sur son support. Ne pas hésiter à forcer

-

-

-

Replacer la seconde biellette de la même façon

-

La grosse tête de la biellette se place côté levier de vitesse

-

Ne pas se tromper d’emplacement du côté de la boîte de vitesse, un support de biellette est libre volontairement pour un réglage.

-

Photo 2 : côté boite de vitesse

-

-

-

Replacer la première biellette de la même façon

-

La première biellette se place juste en dessous de la seconde

-

Biellette n°2

-

Photo 2 : Côté boite de vitesse

-

-

-

Vous venez de changer la tringlerie de boite de vitesse, voici un aperçu des trois biellettes montées.

-

Essayez le passage des vitesse y compris la marche arrière avant de prendre la route.

-

Annulation : je n'ai pas terminé ce tutoriel.

3 autres ont terminé cette réparation.